Date: 2020-03-10

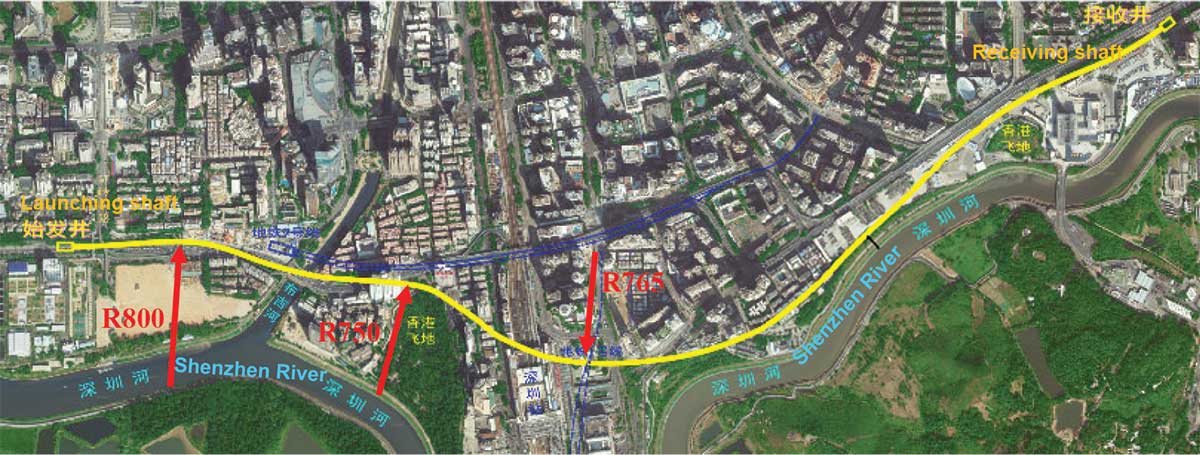

Chunfeng Tunnel is the first bi-directional four-lane highway tunnel in Shenzhen, China, with two decks within one tunnel. The tunnel is 3,603m long; its average radius of curve is R750m and its biggest gradient reaches 49%. The main geological conditions along the tunnel cover granite, fractured rock, metamorphic sandstone and shist. Rock stratum amounts for about 80% of its total length. Meanwhile, the tunnel drives through 11 fault zones with a total length of 431m. And the maximum net head pressure reaches 5.9 bar. The tunnel is being driven by a Φ15.8m Slurry TBM supplied by China Railway Engineering Equipment Group Co., Ltd. (CREG).

There are several challenges during the construction of Chunfeng Tunnel including large excavation section, long driving distance, high water pressure, small radius of curve, many buildings above, fractured stratum, high strength rocks etc. Designed to overcome these challenges, the TBM is equipped with an accessible cutterhead, main drive capable of telescopic movement and swinging, and four-circuit pressure maintaining system. Other innovations include muck treatment with two crushers, online cutter monitoring system, and free grouping of thrust cylinders.

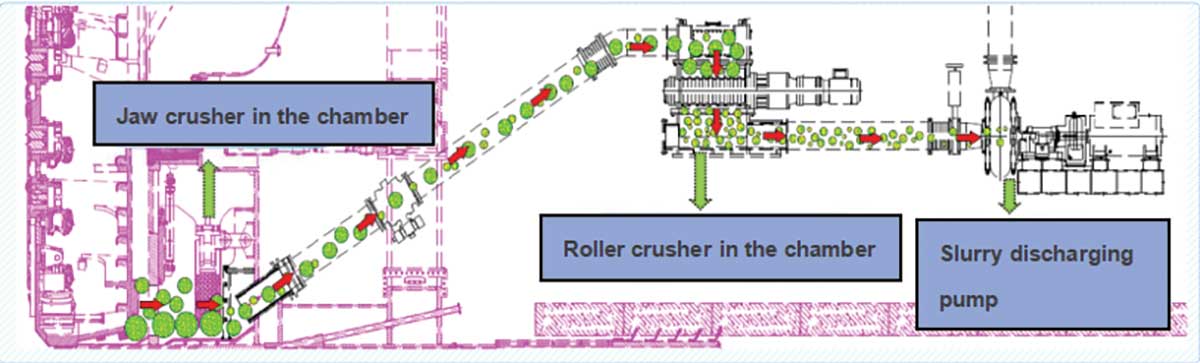

Muck treatment with two crushers: Inside the excavation chamber, larger particles are allowed to pass by increasing the size of the grid, so that there will be less muck at the bottom of the air cushion chamber, the burden of jaw crusher will be lowered, and the muck will be discharged outside quickly. Roll crusher outside the excavation chamber crushes the muck again to reduce the blockage of slurry discharge pump.

Online cutter monitoring system: Except for the central disc cutter casings, it can monitor the temperature, rotation and wear of other disc cutter casings. The monitoring information will be sent to the industrial computer in real time to achieve effective inspection of cutting tools.

Free grouping of thrust cylinders: Based on the default mode of the thrust system, the number of cylinders can be changed to adjust the TBM’s attitude.

The project started in October 2019. Just after launching the TBM, R800m curve and strata consisting of mucky clay on the top and weathered granite in the bottom were encountered. With the application of the technology multi-sensor intelligent detection including excavation clearance measuring system, wear detection of gauge disc cutters, and the tail-skin clearance measuring system, the TBM negotiated the first curve successfully and effectively avoided any possible blockage. Currently, 85 rings have been completed, during which, effective inspection and replacement of cutting tools have been done many times, thanks to the online cutter monitoring system.

To read the original page, please visit https://www.nbmcw.com/tech-articles/metro-tunneling/41503-creg-15-8m-slurry-tbm-solution-for-chunfeng-tunnel-in-shenzhen.html?highlight=WyJjcmVnIiwiY3JlZydzIl0=